Glue Lined Heat Shrink — Advantages And Applications

Adhesive lined heat shrink tubing, commonly known as glue lined tubing, has all the advantages of traditional heat shrink but with one other important feature; a layer of thermoplastic adhesive. Coupled with a hot-melt adhesive inner lining the tubing is made with Polyolefin outer tubing. This layer of glue enables the tubing to offer a better seal and adhesion.

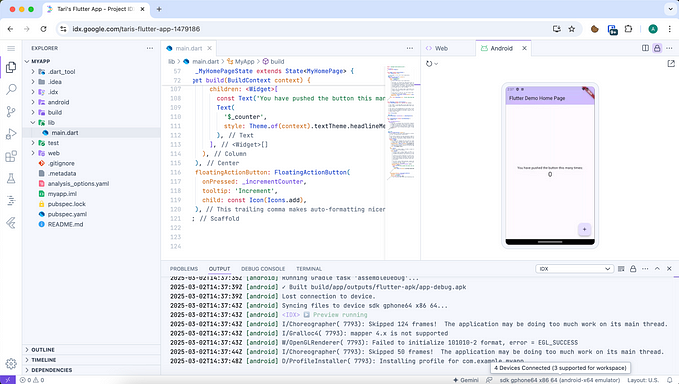

The different properties inherent in glue lined heat shrink tubing along with heat shrink butt connectors make it better suited to certain applications and environments than the standard tubing.

Firstly, it is considerably thicker than normal heatshrink. Obviously it offers a secure and more permanent method of insulating heavier cables although this precludes it from being used in more precise applications.

This means as compared to the standard stuff it is far less flexible, and it won’t coil with the wire like smaller standard heatshrink because of this rigidity.

Glue lined heat shrink tubing with 3m heat shrink butt connectors is widely used in marine applications as it lends itself well to certain environments. It is ideal for sealing mechanical and electrical components and insulating against water and moisture, because of its superior sealant properties. It’s also ideal for effective moisture-resistant insulation of electrical connections and splices.

For instance, when repairing electrical equipment on a boat, a butt connector is often used. These connectors help maximize current flow and protect against corrosion but also use glue-lined tubing to seal out the water. And this sturdy tubing also has the added advantage of relieving some mechanical strain.

As well as the marine industry, adhesive lined heat shrink tubing is widely used in the automotive and electrical industries. Applications include general electrical insulation, mechanical protection and harness/cable bundling. The tubing can be supplied as a continuous product or can be cut into lengths and even printed.